Talk about anything related to Tajima DG15 by Pulse here

Distribution stitch

|

RicamificioOrma Posts: 3

2/19/2019

|

Why the distribution of stitch is not uniform and regular? Especially when you increase the density for 3d puff." "" "" " "

|

|

|

0

link

|

|

Tajima Software Administrator Posts: 549

2/19/2019

|

Hello RicamificioOrma,

To be able to assist you with this, we'd need more information about all of the settings you are using. We recommend contacting your local Pulse distributor to ask if they can take a look at the settings being applied to your segment. Perhaps a random stitch length setting is enabled, among other possibilities.

|

|

|

0

link

|

|

RicamificioOrma Posts: 3

2/20/2019

|

Send the file, in which the stitch are doubled to use the 3d Puff.

|

|

|

0

link

|

|

Kazu Posts: 19

2/20/2019

|

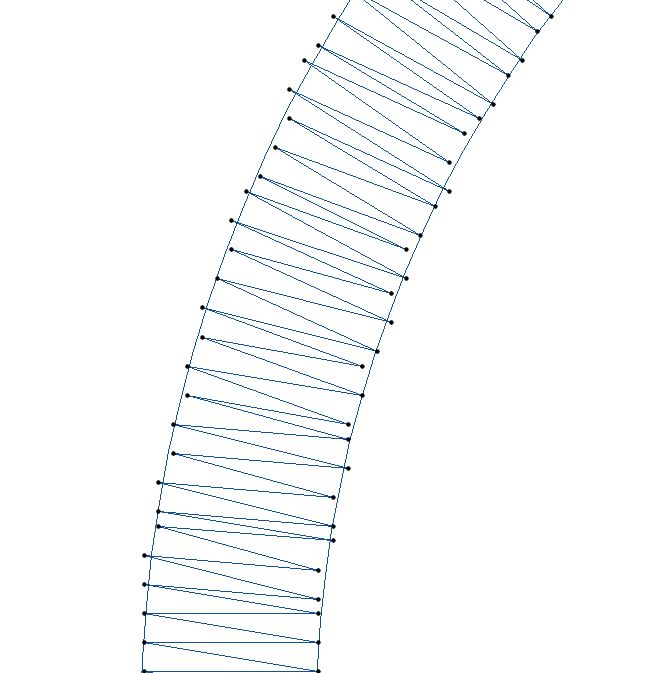

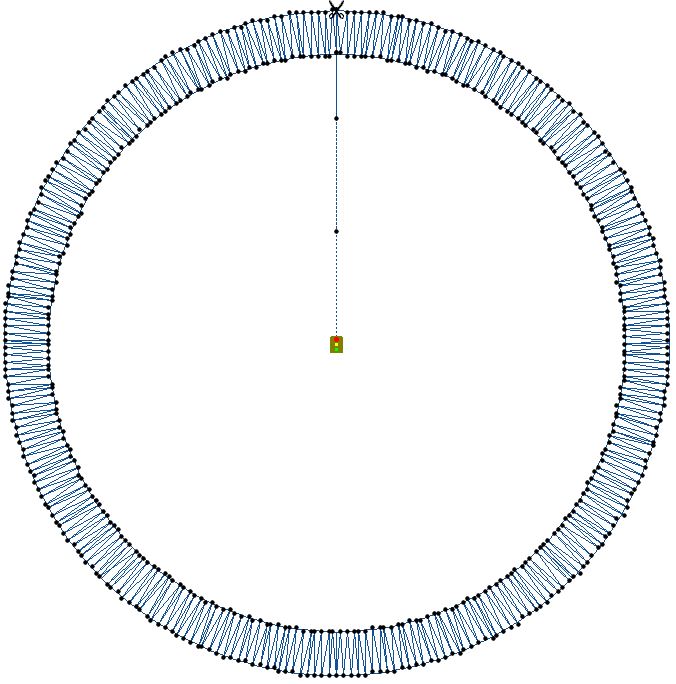

Actually, embroidery machines can move the frame (hoop) in minimum of X:0.1mm/Y:0.1mm. (Minimum stitch length)

So when stitches are generated based on digitized outline/path, stitches are distributed to each 0.1/0.1mm position, never smaller such as 0.05mm.

See the attached.

Grid size is set to X:0.1mm/Y:0.1mm for easier understanding.

Each stitch point is located at intersections of grid, never within grids.

Located at closest intersection point to digitized path line.

If stitches are uniformly distributed along the path, it means stiches are located at points less than Minimum stitch length, such as X0.05/Y0.02.

The machine cannot do that.

Hope my explanation can let you understand.

edited by Kazu on 2/20/2019

|

|

|

+1

link

|